|  |

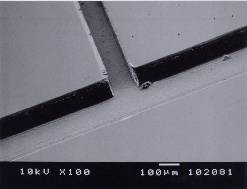

| Fig. 1 A PMMA device (left) and a SEM image of a microchannel (right) | |

| |

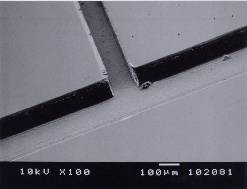

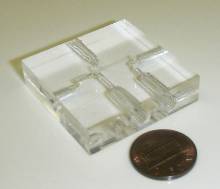

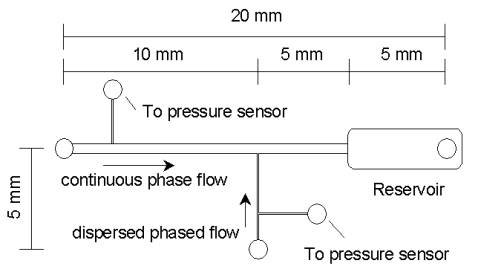

| Fig. 2 Top view of the microchannel network (T-junction type) | |

|  |

| Fig. 1 A PMMA device (left) and a SEM image of a microchannel (right) | |

| |

| Fig. 2 Top view of the microchannel network (T-junction type) | |

|

| Fig. 3 Droplet formation |

|

| Fig. 4 Effect of the velocity of a continuous phase flow on droplet size |

|

| Fig. 5 Effect of continuous phase flow on droplet production rate |